What Is Enterprise Asset Management (EAM)?

Enterprise Asset Management (EAM) is a set of processes, tools, and practices designed to optimize the life cycle management of an organization’s physical assets. This includes everything from initial planning, procurement, and installation to operation, maintenance, and eventual disposal or replacement.

Enterprise asset management (EAM) best practices include using supportive software, implementing preventive maintenance, standardizing data, and improving cross-departmental communication to manage asset lifecycles effectively. Key practices also involve using real-time analytics, creating comprehensive asset inventories, and tracking asset performance with clear goals and KPIs.

Modern EAM solutions often integrate with other enterprise systems to provide comprehensive visibility and control. They offer functionalities such as asset tracking, preventive maintenance scheduling, condition monitoring, work order management, and real-time reporting. These features help organizations reduce downtime, extend asset lifespan, and make informed decisions based on accurate asset data.

Table of Contents

Toggle15 Enterprise Asset Management Best Practices

Here’s a deeper look into some important EAM best practices.

1. Implement Automated Dependency and Asset Discovery Solutions Like Faddom

Automated asset discovery tools like Faddom identify and catalog assets across a network without manual intervention, providing an up-to-date inventory and uncovering previously unknown or shadow assets. By mapping asset dependencies in real time, organizations gain insight into interconnections and relationships, such as which systems rely on specific servers or infrastructure components.

This visibility is crucial for root-cause analysis during downtime and for planning upgrades or changes without disrupting crucial services. Real-time mapping ensures that the asset inventory and dependency maps always reflect the current state of the environment. This prevents errors associated with outdated documentation and helps teams respond quickly to incidents or vulnerabilities.

2. Establish a Centralized Asset Repository

A centralized asset repository consolidates all asset-related information into a single, authoritative system. This eliminates silos, reduces duplication, and ensures that every stakeholder, from maintenance teams to finance, accesses the same up-to-date data. Centralization simplifies asset tracking, enhances coordination between departments, and simplifies compliance by providing a clear audit trail and lifecycle history for each asset.

The repository should support detailed asset records, including location, status, ownership, maintenance history, warranties, and configuration data. When connected with other enterprise systems such as procurement or ITSM tools, a centralized repository becomes a useful source of operational intelligence.

3. Standardize Lifecycle Processes

Standardizing lifecycle processes ensures that every asset is acquired, operated, maintained, and retired consistently across the organization. This reduces risk, simplifies training, and delivers predictable results, as procedures are based on proven best practices rather than ad hoc decisions. It also supports audit and compliance efforts, providing clear documentation of how assets are managed from cradle to grave.

Standardization should cover key phases such as acquisition, configuration, preventive maintenance, incident response, and decommissioning. Documenting these procedures reduces errors, supports regulatory compliance, and enables automation. When lifecycle management is standardized, organizations can benchmark performance, pinpoint inefficiencies, and drive continuous improvement across the asset portfolio.

4. Use Condition-Based and Predictive Maintenance

Condition-based maintenance involves monitoring asset health in real time and only performing maintenance when certain thresholds or conditions are met. This approach reduces unnecessary scheduled work and helps prevent both under- and over-maintenance. Sensors, IoT devices, and telematics gather data on temperature, vibration, usage, or other indicators, allowing maintenance teams to intervene just before a failure is likely to occur.

Predictive maintenance uses data analytics and machine learning models to forecast when an asset is likely to need servicing or is at risk of failure. This strategy maximizes asset uptime and longevity while lowering repair costs and minimizing emergency interventions.

5. Assign Ownership and Accountability for All Assets

Establishing clear ownership and accountability for each asset ensures that someone is responsible for its performance, compliance, and upkeep throughout its lifecycle. This helps avoid ambiguity when issues arise, speeds up response times, and encourages proactive management of maintenance and decommissioning activities. Ownership can be assigned at various levels (by department, function, or individual) depending on organizational structure.

Documenting asset ownership in the EAM system enables tracking and accountability for updates, audits, and change management. With assigned accountability, organizations can easily identify who to contact for specific asset issues and hold stakeholders responsible for ensuring data accuracy.

6. Prioritize Asset Criticality

Prioritizing assets based on criticality ensures that maintenance, upgrades, and investments are focused where they have the most significant business impact. Criticality assessments factor in variables such as asset value, risk of failure, impact on production, and safety or regulatory consequences.

By ranking assets, organizations can optimize resource allocation, ensuring mission-critical systems receive timely attention while less essential assets follow a different maintenance strategy. Maintaining a dynamic, regularly updated criticality matrix allows maintenance teams to respond swiftly to changing business requirements or operational risks. This prioritization supports decisions regarding spare parts inventory, staff deployment, and capital planning.

7. Integrate EAM with ITSM, CMDB, Procurement, and Finance

Integration between EAM and other key enterprise systems like IT Service Management (ITSM), Configuration Management Database (CMDB), procurement, and finance eliminates data silos and improves cross-functional workflows. For example, linking EAM with procurement systems automates asset ordering, while integration with finance simplifies lifecycle cost tracking and depreciation.

Connecting with ITSM and CMDB ensures accurate asset status during incidents or changes, simplifying support processes. Bidirectional integration supports real-time updates and synchronization across platforms, preventing data discrepancies and manual entry errors. It also drives more insightful analysis and reporting because all relevant asset and operational data is available in context.

Learn more in our detailed guide to CMDB discovery

8. Maintain Accurate Software License Management

Effective EAM includes managing software assets and licenses to ensure compliance and avoid costly penalties. Maintaining an up-to-date inventory of all installed software, license keys, entitlements, and usage metrics enables organizations to match actual consumption with purchased agreements. This prevents both underutilization (wasted spending on unused licenses) and non-compliance (risking audits or legal action).

Automation aids in tracking installations, updates, renewals, and expirations, alerting teams to risks or renewal opportunities. Integrating software asset management with EAM offers a holistic picture of all tangible and intangible assets, supporting audit-readiness and informed procurement planning.

9. Adopt Configuration and Change Control Policies

Strong configuration management ensures that asset records accurately reflect current configurations, dependencies, and operational status. Formal change control policies require authorization, documentation, and testing when assets are modified or upgraded. This reduces the risk of unauthorized or poorly documented changes introducing failures or security vulnerabilities.

EAM systems should capture and correlate configuration and change records to provide a complete history of each asset. This linkage aids troubleshooting, escalates anomalies, and simplifies compliance audits by demonstrating controlled management of assets and changes.

10. Implement Risk-Based Asset Monitoring

Risk-based monitoring tailors the level of asset oversight to the potential impact of a failure or compromise, rather than treating all assets equally. High-risk assets, such as those essential for safety, production, or compliance, receive deeper monitoring and more frequent inspections. Lower-priority assets may be checked less often, freeing resources for higher-value activities.

Using risk assessments and historical data, organizations can adjust monitoring levels dynamically as risk profiles change. This approach allows for the early detection of issues in critical assets, supporting rapid intervention and reducing negative outcomes.

11. Use Analytics and Dashboards for Visibility

Advanced analytics and dashboards offer real-time visibility into asset status, performance trends, and potential issues. EAM systems should provide configurable, role-based dashboards that highlight key metrics such as downtime, maintenance backlogs, asset utilization, and costs. These insights enable managers to identify inefficiencies, predict failures, and optimize maintenance schedules.

Dashboards support data-driven decision making and foster accountability by giving each stakeholder immediate access to relevant KPIs. Over time, analytics can reveal areas for process improvement, inform capital planning, and demonstrate ROI on asset investments. Visualization of asset data also helps justify spending and resource allocation to executive leadership.

12. Standardize Asset Tagging (QR/RFID)

Consistent asset tagging using technologies such as QR codes or RFID labels provides fast, accurate tracking throughout the asset lifecycle. Standardized tags support automated check-in/out, maintenance logging, location updates, and compliance audits. This reduces errors, speeds up inventory activities, and helps prevent loss or theft.

Implementing a tagging standard ensures compatibility across sites, departments, and asset types. It serves as the basis for automation solutions like mobile scanning apps and integrated warehouse or field service tools. When asset tags link directly to the EAM system, staff can access real-time status and history by scanning a code, improving field efficiency and record accuracy.

13. Maintain Strong Vendor and Contract Management

Effective EAM involves managing relationships with vendors and tracking asset-related contracts such as warranties, service agreements, and support SLAs. Centralized contract management ensures timely renewals, renegotiations, and adherence to agreed-upon service levels. It reduces the risk of lapses leading to unsupported assets or missed financial obligations.

Vendor performance should be regularly assessed using KPIs like asset uptime, repair responsiveness, and contract compliance. Integrating vendor and contract data with the EAM system offers a holistic view of external dependencies, supports strategic sourcing decisions, and strengthens negotiation positions. Efficient contract management also ensures timely claims processing for repairs and replacements.

14. Automate Repetitive Workflows

Automating routine asset management tasks, such as work order generation, preventive maintenance scheduling, inventory reordering, and compliance reporting, boosts efficiency and reduces human error. Workflow automation enables faster response times, ensures standard process adherence, and allows skilled staff to focus on higher-value tasks.

Most modern EAM systems support automation through business rules and integration with IoT or ERP platforms. Automation also supports scalability as asset portfolios grow, as it reduces the incremental overhead for managing new assets or locations. By minimizing manual intervention for predictable, repetitive activities, organizations can sustain process rigor and lower operational costs.

15. Conduct Regular Audits and Compliance Checks

Scheduled audits validate the accuracy of asset data, confirm regulatory compliance, and uncover discrepancies such as unauthorized changes or missing assets. Compliance checks are essential for industries with strict safety, environmental, or licensing requirements. Regular audits also support insurance claims and help avoid fines or penalties due to incomplete or inaccurate records.

EAM systems can automate much of the compliance reporting process by flagging assets due for inspection, tracking audit outcomes, and maintaining an immutable history for each asset. Transparent audit trails foster trust in asset data and demonstrate diligence to regulators and stakeholders.

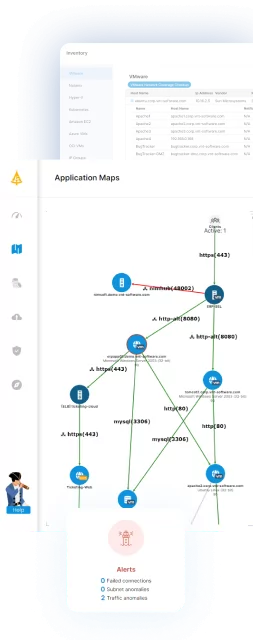

Enterprise Asset Management with Faddom

For large enterprises, the biggest challenge in EAM is no longer simply tracking assets in isolation. Instead, it lies in understanding how these assets interact in complex, hybrid environments. As infrastructures expand across data centers, cloud services, and various regions, maintaining asset accuracy becomes difficult, dependencies can be unclear, and changes introduce risk. Traditional EAM systems heavily rely on manual updates, periodic discovery, and static records, making it challenging to maintain a real-time and reliable view at the enterprise scale.

Faddom addresses this challenge by providing agentless, real-time application dependency mapping that continuously discovers servers, applications, and their live relationships across hybrid environments. By monitoring actual traffic and dependencies, Faddom ensures that asset data remains accurate, uncovers hidden dependencies that could lead to risk and downtime, and supports critical enterprise functions, including change impact analysis, risk-based prioritization, CMDB accuracy, and large-scale transformation initiatives. This continuous operational view offers enterprises the foundational insights needed to manage assets effectively, reduce outages, and make informed decisions across IT, operations, and the broader business.

Explore how Faddom can enhance your enterprise asset management by requesting a demo using the form on the right!